Rural Innovation Application Center

Rural Innovation and Application Centre

Setup in Talwara block of District Hoshiarpur, The Rural Innovation and Application Centre (RIAC) is an initiative to address the socio- economical challenges faced by rural communities and aims to enhance their well-being, livelihood and economic standard through S&T based solutions/interventions. RIAC has made significant contributions in the development, demonstration and transfer of affordable rural technologies in areas including sustainable agriculture, bio-energy, value-added food products etc.

RIAC is working in line with the mandate set by Govt of India towards Aatmnirbhar Bharat (Self-reliant India). The Centre is adopting Social Entrepreneurship Model for boosting small-scale farming enterprises and rural entrepreneurs in the State.

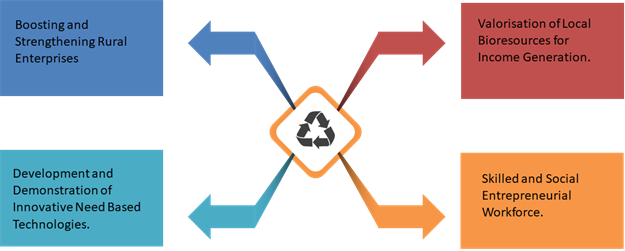

RIAC-GOALS

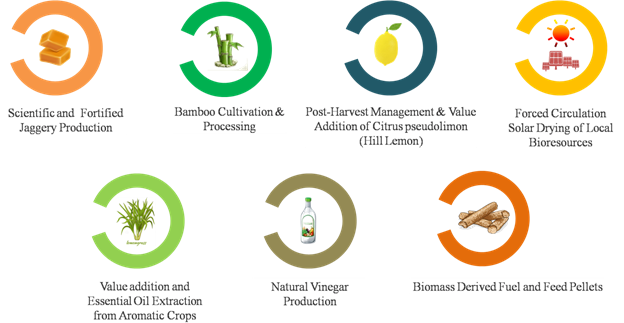

TECH-INTERVENTIONS BEING PROMOTED BY RIAC

SCIENTIFIC & FORTIFIED JAGGERY PRODUCTION

Jaggery is a well-known traditional Indian sweetener made from Sugarcane Juice and consumed worldwide. Jaggery industry constitutes one of the major Agri-processing sector in India and is a traditional enterprise of various States including the State of Punjab. India is also the largest producer and consumer of jaggery, contributing more than 60% of total global production. Due to its vast medicinal properties and nutritionally properties, the demand for good quality jaggery is increasing steadily.

However, in spite of being a dominant cottage industry, jaggery remains largely unorganized and is still being produced by following traditional methods lacking in quality and hygiene. Further, the jaggery industry is prone to inconsistencies due to lack of technological interventions, scientific protocol & indiscriminate use of chemical clarificants thereby yielding marginal profits to farmers. Hence, there is a dire need to sensitize & make farmers aware of the technological interventions, scientific and hygienic method of jaggery processing as well as use of safe & natural herbal clarification agents for obtaining quality jaggery.

The jaggery industry offers lot of potential in view of its growing market demand and the role it perceives in creating employment opportunities for million of rural households. To boost the traditional rural enterprise of jaggery production in the State, PSCST has collaborated with Punjab Agricultural University to:

- Develop an optimized process for safe processing of Sugarcane juice into quality jaggery with better shelf life and stable taste.

- Use of herbal plant extracts as clarification agents for obtaining chemical free jaggery.

- Development of fortified nutritional jaggery as a functional food.

- Demonstration of modern Jaggery processing units (2 No) for boosting rural entrepreneurship.

BAMBOO CULTIVATION & PROCESSING

Typically known as Green Gold of the Forest, Bamboo is emerging as a super crop in the 21st century owing to its multifarious uses in the construction, energy, food, cosmetics and many more industries. Being a versatile grass, Bamboo can be transformed into various innovative & market driven value added products.

In view of its extensive applications as a bio-resource and for providing sustainable income avenues in the rural areas, Govt. of India made an amendment in Section 2(7) of Indian Forest Act, 1927 and categorized bamboo as grass (earlier tree) that can be cultivated on private land or homestead land by farmers without requiring a felling permission or transit permission from any state forest department.

The kandi area of State has great potential for its cultivation & processing as the plant is fast growing & highly renewable bioresource. Further, being drought tolerant, most suitable for cultivation in rainfed areas and requiring fewer nutrients to grow. The kandi region of the State has exclusive bamboo bearing forests at Karanpur (1456 ha), Bindraban (1203 ha) and Nandbir region (734 ha). The commonly found bamboo species in these forests include Dendrocalamus hamiltonii (Magar bans), Dendrocalamus strictus (Lathi bans) and Bambusa Bambos (Kanta bans).

With an aim to uplift the socio-economic condition of rural farmers in Kandi region, PSCST is promoting Bamboo cultivation and its value-added products for generating rural community enterprises. So far bamboo cultivation has been promoted in 20 adopted villages of Talwara block. Sensitization workshops/capacity building programmesare being organized from time-to time to empower the local farmers/Self Help Groups.

POST-HARVEST MANAGEMENT AND VALUE ADDITION OF CITRUS PSEUDOLIMON (HILL LEMON)

The Kandi area of state is endowed with natural bioresources including Citrus pseudolimon, commonly known as Hill lemon / galgal found abundantly in the area. Except a small fraction of the fruit that is being used for making pickles, it remains an unutilized bioresource and is wasted. Being a citrus fruit, it has potential to yield useful value added products viz. pectin, citrate, essential oil and limonene therefrom, edible color and other phytochemicals. In order to utilize this abundantly bio resource, PSCST collaborated with Center of Innovative & Applied Bio processing to demonstrate the technologies for production of value-added products including pectin etc.

Pectin is a natural polymer found in cell walls of non-woody plant cells, whose increasing use as gellingagent by the food industry is rapidly expanding into other industrial sectors like pharma, cosmetic &personel care etc. The major part of the commercial pectin is being produced from the citrus fruits (85%) apple pomace (14%) while small fraction being obtained from sugar beet. Pectin has main usage as a gelling agent and hence has high demand from food industries dealing in jams and jellies as well as has usage as thickening agent and stabilizer in food based industry.

PSCST & CIAB jointly setting up a pilot scale unit at Talwara to demonstrate the technology for optimal utilization of this bio resource. CIAB has standardized the technology prototype at laboratory scale and studies wrt characterization of pectin & other value added products has also been carried out by CIAB.

FORCED CIRCULATION SOLAR DRYING OF LOCAL BIORESOURCES

The Shivalik belt of Punjab is one of the most degraded rain-fed agro eco systems in the country. The agriculture income in this area is too meager to sustain the livelihoods. However, this belt of Punjab called ‘Kandi area’ is endowed with about 140 naturally growing species of medicinal & aromatic plants. Many of these SHGs operational in the region are engaged in livelihood generating activities based on these local bio resources. It is observed that due to lack of post harvest infrastructure in the region, individuals/SHGs engaged in cultivation & processing of medicinal & aromatic plants face challenges w.r.t post harvest management of the produce. It is estimated that about 30% of the raw material reaching the manufacturers is being rejected because of poor quality.

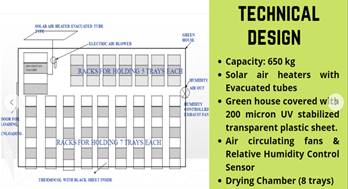

The major value addition activity carried out by these SHGs involve sun drying of bio resources, though it is more economic process, but it has some associated problems like, uneven moisture content which causes fungal infestation in finished products, damage due to rain, insects, dirt contamination due to long exposure in open and renders the product poor in quality. Punjab State Council for Science & Technology (PSCST) felt that an S&T intervention at this level can have enormous impact on socio-economic development of the area. Accordingly, collaboration was made with PAU who had developed a technology of Forced Circulation Solar Dryer (FCSD).

PSCST under Sustainable Agriculture Rural Transformation Holistic Initiative (SARTHI) of DST-GOI promoted the technology of FCSD in Kandi area of the State. The technology due to evacuated tube collectors and forced circulation drying offered distinct advantage in terms of achieving higher temperature of 50-60° rapidly within 1 hour and its prolonged maintenance compared to conventional solar drying which is based on simple green house effect. PSCST led to demonstration of two Forced Circulation Solar Dryers one at PSCST’S Processing Facility at village Fatehpur and second at village Dharampur, both managed by local Self Help Groups. SHGs were facilitated to dry local resources using these units for livelihood generation, which otherwise were being dried using conventional open sun drying yielding low quality produce, hence fetching less market price to the local community. FCSDs usage has led to production of quality and hygienic products, free from dust & pests with enhanced shelf life. Based on success of these units, Govt. of Punjab has replicated technology at ten more places in the state.

FIELD DEMONSTRATION OF CULTIVATION & PROCESSING OF SELECTED AROMATIC CROPS IN DHAR BLOCK OF DISTRICT GURDASPUR, PUNJAB

Dhar block of district Gurdaspur falling in Kandi area of Punjab is primarily rainfed, has small land holdings, undulating topography and problems of soil erosion, lack of soil moisture, low fertility, frequent attack of stray animals on cultivated land because of natural pastures having been infested with Lantana weed. Hence, the returns from agriculture are meagre. In view of this, farmers of Dhar block had urged PSCST & Ministry of Science & Technology, Govt. of India to suggest S&T interventions for socio-economic development of the area. Thus, with the support of Department of Biotechnology, Govt. of India an end-to-end demonstration project has been taken up to demonstrate the feasibility of cultivation of selected aromatic crops in this block.

The implementation partners included Scientific Research Centre (KSRC) Mumbai, PAU’s Regional Research Station, Gurdaspur and Unati Cooperative Marketing-cum-Processing Society Ltd., Talwara. Under the project, agro technologies were fine tuned by RRS Gurdaspur under local conditions for optimal yield production of five aromatic crops viz. Lemon grass (Cymbopogon flexuosus), Citronella (Cymbopogon winterianus), Palmarosa (Cymbopogon martini), Patchouli (Pogostemon cablin) and Geranium (Pelargonium graveolens).

The successful cultivation of aromatic crops was demonstrated at about 50 acre farmers’ field, training programmes were organized for capacity building of farmers, two farm scale distillation units were set up for value addition through extraction of essential oils and marketing tie-ups arranged for its buy-back through Unati and Keva Biotech, the industrial arm of Kelkar group. One of the progressive farmer was also honoured by District Administration on the eve of Independence Day.

NATURAL VINEGAR PRODUCTION

Vinegar has been used since ages and is important constituents of European, Asian & other cuisine. It is used as flavouring agent, preservative and ingredient for salad dressing etc. The major commercial demand of vinegar is being presently met through availability of low cost synthetic vinegar which has no nutritive value and is harmful to the consumers. The awareness on this aspect is completely lacking among consumers.

Natural vinegar prepared from fruits & vegetables has immense potential due to its nutritive & medicinal properties. It is considered as superior food additive as it contain essential amino acids from its fruit/vegetable source. Due to its enhanced nutritive value, the demand for natural vinegar is increasing consistently. In order to promote the natural vinegar production, PSCST joined hand with Department of Microbiology, Punjab Agricultural University to scale up the technology for its commercialization.

Initially, PAU standardized the technology for vinegar production utilizing sugarcane juice i.e various fermentation parameters using Saccharomyces cerevisiae strain 35 followed by secondary fermentation with Acetobacter aceti NRRL 746 under batch conditions (50L scale) which yields average vinegar (with acidity 4.5-4.8% w/v) recovery of 70-80% in 22-28 days. Efforts were made to achieve reduction in fermentation time by optimizing agitation rate during primary fermentation, recycling of vinegar batches (replacement of 2/3rd volume of produced vinegar with ethanol) and immobilized cell culture i.e. semi-continuous culture using cells adsorbed on wood shavings.

Two demonstration units were set up one each at Talwara (within the processing facility set up by the Council in collaboration with Unati Cooperative Society) and the other at Science Technology Entrepreneurs’ Park, Thapar University, Patiala.

Further, efforts were also made to utilize the other local bio resources and process was optimized for vinegar production from guava, amla, sugarcane, jamun etc. The technology was promoted in kandi villages of Districts Hoshiarpur and Ropar. About 500 beneficiaries from 10 villages (self help groups’ members, rural women, farmers, small entrepreneurs) were made aware about the technology through awareness workshops. Hands-on training programmes on complete technology protocol viz. fermentation process, starter culture, harvesting, recovery, bottling & pasteurization were organized for beneficiaries keen to take up the technology. Handholding was provided to nine self help groups who started domestic vinegar production.

Presently, the technology has been scaled up for production of natural vinegar at a scale of 1 lakh liters per month at Unati Cooperative Society, Talwara. The nautaral vinegar produced have found inroads not only in various parts of India but in the international markets also.

BIOMASS DERIVED FUEL AND FEED PELLETS

Content being updated….